Use the fiber you have

I have a bit of a stash. Knitting yarn is confined to my clothes closet. I figure that is a good way to limit both the amount of clothes (never a problem) and the amount of knitting yarn I am tempted to buy (always a problem). And I consider the weaving yarn a business asset though I have tried to use up the undyed yarn stored in huge plastic bins this year (before buying more of course). I am not even going to mention the hand-dyed tapestry yarn stash. That is sacred.In the interest of cleaning out the dark corners of my closets of UFOs (UnFinished Objects), I pulled them all out last weekend. I was a little shocked. I mean, I knew that there were four sweaters that needed finishing, but seeing the pile was kind of like staging my own intervention. I found these almost-finished projects:

- 3 baby hats (and I suspect 8-10 more are hiding in the stash)

- 4 adult-sized sweaters, one a long-promised gift

- 5 scarves needing only ends sewn in and blocking

- 7 elf sock Christmas ornaments

- 1 shawl (ends and blocking)

- 1 felted bag missing only a lining and the handle sewn on

- 2 kid toys (monsters missing most of their vital parts still!)

- 1 bath set (ends sewn in only--and there were only 4 ends)

- 1 pair of socks

- 1 friend's sweater from which a dog had chewed a button and left a hole the fixing of which was an exchange for some awesome spinning fleece (I clearly got the better end of this deal)

- 1 organic cotton baby blanket needing only the lining sewn in. Lining fabric is present.

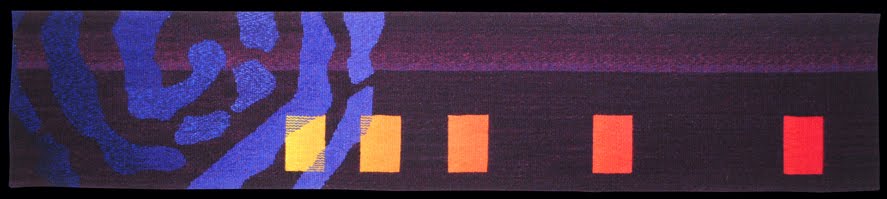

- 1 woven baby blanket with pick-up text that says "Giggle"

It took me the length of one movie (The Secret Life of Walter Mitty) to sew in the tails of a large percentage of these projects which are now in line for blocking. The big projects remain but I have hope that I will be able to plow through all of them in the next few months.

So all of this brings me to what I did yesterday.

I took a little field trip to Mitchell, Nebraska. Why Nebraska you ask? Because the Brown Sheep Company is there. What do they make?

You guessed it. Yarn.

I was only going to buy the wool warp I wanted to try. Really. But then I found out that their mill store sells their seconds yarn (the skeins with more than one knot in them) for unbelievable prices... and then there was the brand new knitting book from Interweave with the very cool patterns and the yarn was right there... and, well, I brought home two bags worth. I know it won't fit in the closet stash with all those UFOs. So it is back to doing the finishing.

Unfortunately (or fortunately for you, dear readers), Brown Sheep Co. doesn't allow photos in their mill. So you are spared the lengthy photo/video tour of the facility (if this is disappointing to you, you can visit my prior tours HERE and HERE and HERE). Just believe me when I say that it was wonderful and I had a fantastic time.

Here are a few of the things that interested me:

- They source their wool locally. They get their wool which is Rambouillet and Columbia from local sheep farmers in Nebraska, Wyoming, and the front range of Colorado. I like this a whole lot.

- Their process is worsted (as opposed to Harrisville which is a woolen mill).

- The raw wool is processed in South Carolina. They get it back as lovely combed top.

- All the wool is white. They spin it first (except for some of the heathered yarns they do where they dye the roving first), steam it, ply it if it is not a single... there are multiple times they have to skein the stuff... and then they dye it.

- The roving was coiled in four-foot tall cylinders perhaps a foot and a half in diameter. The ones that had a mix of white and black created an especially lovely pattern--all that lovely top coiled regularly in a mix of black and white. Really you should see it.

- I haven't before seen the huge dyeing machines they use before. They use acid wool dye and they do have a hand-dyer for some of their lines. But the solid colors go on trays in one of the huge square dyeing machines. Their largest will dye 200 pounds of wool at a time. (!!!) They recycle the water and what they can't use again is treated and evaporated from a large lagoon.

- The skeining machines were super cool. Boy do I wish I had one of those!

- There is a very cool label machine that puts on the labels for many of the kinds of yarn, though all the paper labels you see on their lines are applied by hand.

- In case you're interested in weaving tapestry with their yarn, I would recommend Brown Sheep Waverly for this purpose. It comes in hundreds of colors and you can buy it in 8-yard skeins which is great for small-format work.

There is a fiber festival in Scotts Bluff in September that Brown Sheep participates in heavily including offering classes and factory tours. Let's go!

We also stopped at Scott's Bluff National Monument, took a hike to the top of the bluff, and had some fun with the Oregon Trail replica wagons that were there. How much yarn do you think I'd have if I had to move everything I owned across the west in one of these?

I am going to try again to love the fiber I have. I do think a stash is absolutely vital to the life of a fiber artist. I'm just not sure how many skeins of hand-dyed sock yarn I can realistically knit in the next 40-50 years.

Well that was brave of you to do that I on the other hand love to live on the edge of denial as to the amount I need I am always in fear of running out or not have just that color when I want it. This is also a problem when we go for trips in the motor home. Thank God I have the best husband in the world and he just finds more room for one more tub.

ReplyDeleteI'm trying to imagine packing all my worldly goods on one of those wagons....

ReplyDelete